For the second installment in the series, I interviewed Karen Hostetler and Valerie Spanos, the principals of Mountain Meadow Wool in Buffalo, Wyoming.

Karen and Val, two of my favorite people!

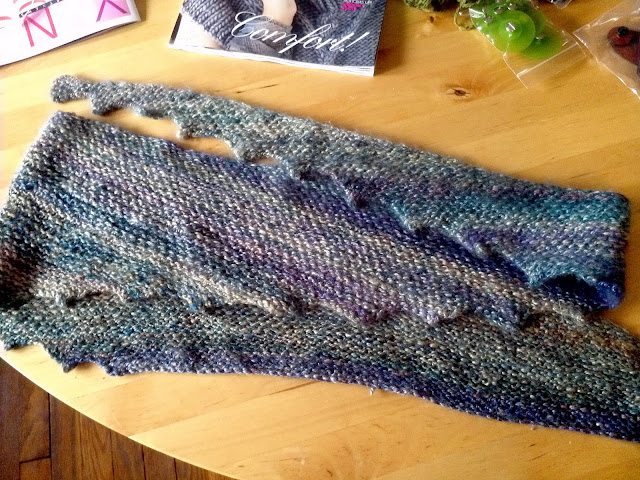

They are some of my favorite people and I love, love, love the yarn. I designed this piece (Morning on the River Kimono, from the Jul Topografie Collection, and soaked in Unicorn Fibre Products to block–of course!) in their Sheridan, a 3 ply bulky merino.

Squishy, nice stitch definition, beautiful color, warm...what else could you ask for?

I will wear this kimono every day in the winter! If you are a Ravelry member, hop on over here and see the gorgeous projects other people are making with the yarns. Spinners, they make roving also–it is super-yummy!

YarnSuperhero: I think it is so cool what you are doing, and your yarn is delicious! All of my yarnie friends who know about you say that Mountain Meadow Wool is “Yarn with a capital Y.” Why is your yarn so much more alive than other yarns?

Karen and Valerie: This is a great question and we really believe that it is the quality of the wool from our great growers that makes a big impact on our yarns’ aliveness. The wool is sourced from the best fleeces in our state and not blended with any lesser grades.

We use the words “gently processed” in our advertising and it is true. The wool is not subjected to harsh chemicals at any time and our soaps and oils are environmentally friendly and gentle. Of course, we also believe that the environment where our yarn is created is so full of good energy, from the workers, to the beautiful scenery near our location, that we can’t help but make delicious yarn!

YS: I totally agree! You guys are so wonderful, and make what you are doing so meaningful, that it gets embedded in your product, for sure! Why did you decide to open your mill? What was it like getting started?

K & V: Valerie and I initially wanted to open a natural toy store for children and families! We both had raised lambs and we both loved wool, so we thought it would be great to have wool products from the area ranches to resell, but there was nothing available. We hauled a bale of wool to Canada for processing and then we started questioning why there wasn’t a mill in Wyoming. That started the ball rolling and the mill was born.

It was a daunting task, getting the mill started, from finding equipment, to learning the intricacies of yarn making. We are always questioning and wanting to know the answers, so we started looking into grants. Thus far, we have received several research grants from the USDA-SBIR Program and we continue to work with this program. Our latest grant is for treating the effluent from the washing system so that as we learn more, we can enable smaller mills to be more environmentally friendly.

YS: Without giving away any of your trade secrets, what are some of the more tricky aspects of processing wool and yarn?

K & V: We have beautiful fine wool in the Mountain West, but the fibers are short. This presented a huge challenge for us to spin the fiber into excellent yarn, but we learned how to do it and can now make just about any weight of yarn that is needed. Yarn making is a skill and getting the weights correct is always tricky. Our plant manager went from 30 years working in a sawmill, to a yarn mill, but he is great at troubleshooting.

Who is that behind the fiber?

YS: What is traceback?

K & V: From the very beginning, we felt strongly about helping provide viability and sustainability to the ranches that have been in the West for over 100 years. This is a big vision and in an effort to keep this way of life profitable and to allow the vast open spaces of the West, really open, we decided to tie our profit into the profit of the ranchers themselves.

We select our growers based on their fiber quality and then the wool is followed through the system so that we always know which grower’s product is being run. This is more work for us, but it ties the family ranch to the consumer and makes a nice connection. The consumer knows exactly where the wool comes from, by information on the tag, and the rancher has pride in seeing their raw fiber made into something beautiful.

YS: What a neat idea! What things have been the most surprising, or unexpected about being in the yarn business?

K & V: Everything has been surprising, but the biggest surprise has been the relationships that abound within the industry, from the manufacturers to the dyers, to the yarn shops, there is a great connection between all. Through these connections, we have really grown our business. It has been invaluable to talk with these people and the customers to really know where the industry is heading and what the consumer wants. Everyone is friendly and open, this was a nice surprise!

YS: I agree, when I first got into the fiber arts business, I was struck by how people try to make connections with each other, not just about their enjoyment of the crafts they are involved in, but even on a more personal level. I have made many friends in this little world, and anyone who goes to the trade shows knows that there are way more hugs than handshakes happening! What is the most fun part of your job?

K & V: Because of the variety of the work, there is never a dull moment and Valerie and I never know what to expect. The best part is when we hear people reacting to our yarns and loving them. That is so great and satisfying. Or when one of our ranchers comes in and sees the yarn being made from his flock and he just stands there watching and smiling, then says, “Keep making that string stuff!”

YS: What is your typical day at the mill like?

K & V: We start off the day by going out onto the production floor and talking with the workers on the jobs we are working on and get the day lined out. The rest of the morning is spent checking out our email, fulfilling orders, visiting with customers and working in the dye kitchen if it is needed. We try to spend the hours after lunch on different projects and work mostly in the office. The day ends with checking our emails again and closing out the day with the workers.

YS: How much of a challenge is it to try to keep your operations as environmentally friendly as possible?

K & V: Our biggest challenge has been in the washing and cleaning of the wool. We use Unicorn Products and feel confident in their environmental impact. We really are very environmentally friendly in our production. We stay away from harmful chemicals and we recycle as much wool waste as we can. The cleaner wasted is used in our felt products, like dryer balls and cleaning pads. the dirtier waste is bagged up and we resell some and the rest we use in items like floor absorbent pads and pet beds. The water from the washing is our next issue. We have received a USDA grant on an in-house effluent treatment system which we will be working on over the next 2 years.

YS: I’m happy that you have switched to Unicorn Products at your mill. Can you tell me what you like the most about them and what made you decide to change from the products you used previously?

K & V: Clean wool is important to us and to our customers, so the first thing we look for in a cleaning product is its ability to get the wool clean. Unicorn products are working very well for us, and compared with the product we used before, we have to use a lot less to get the job done. Unicorn Products smell fresh and clean and the heavy grease content of our fine wool is being removed well. We now have used these products for a year and our yarn quality has improved because of it.

YS: A big thanks to you both for the interview. Keep up your great work!

My first thought was that I would measure out equal amounts of fiber for each small batch. Many people have done side-by-side

My first thought was that I would measure out equal amounts of fiber for each small batch. Many people have done side-by-side

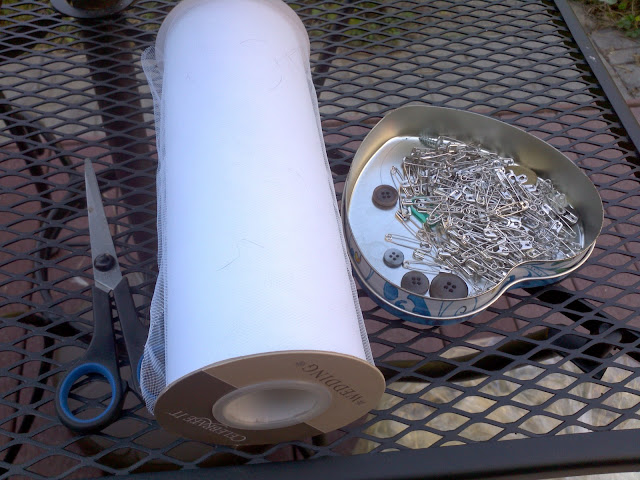

Here are some of the other tools I used, loosely following the Beth Smith tulle envelope

Here are some of the other tools I used, loosely following the Beth Smith tulle envelope  Here are some of the lightest colored locks. But you can see the aforementioned “farm dirt” causing these silvery locks to look yellow. It’s important not to put too much stock in the color of your fleece when it is still dirty.

Here are some of the lightest colored locks. But you can see the aforementioned “farm dirt” causing these silvery locks to look yellow. It’s important not to put too much stock in the color of your fleece when it is still dirty. Nice and fluffy, though. Not much VM, and nice crimp. Coopworth is not the softest wool out there, but it feels good to me and will make nice socks or a jacket, maybe.

Nice and fluffy, though. Not much VM, and nice crimp. Coopworth is not the softest wool out there, but it feels good to me and will make nice socks or a jacket, maybe. See how shiny it looks? Still unwashed, mind you. And aren’t those black strands interesting? This gave me the idea to sort for color.

See how shiny it looks? Still unwashed, mind you. And aren’t those black strands interesting? This gave me the idea to sort for color. You can see there is a lot of color variation within this one fleece. There were very white looking locks, and some dark grey, but most of it was “medium.”

You can see there is a lot of color variation within this one fleece. There were very white looking locks, and some dark grey, but most of it was “medium.”

I sorted, and packed…

I sorted, and packed… And sorted and packed,

And sorted and packed,

Kinda brown, but I’ve seen a lot worse! I follow the two washes with one or two warm water rinses, and incorporate a squirt of the Unicorn Fibre Rinse into this step. It will help soften the fleece for spinning and makes it smell nice, but not perfumey. I like the somewhat sheepy smell, and I never try to get out all of the lanolin. I like a little in there because it helps the locks spin easily and it is a nice moisturizing treatment for my hands.

Kinda brown, but I’ve seen a lot worse! I follow the two washes with one or two warm water rinses, and incorporate a squirt of the Unicorn Fibre Rinse into this step. It will help soften the fleece for spinning and makes it smell nice, but not perfumey. I like the somewhat sheepy smell, and I never try to get out all of the lanolin. I like a little in there because it helps the locks spin easily and it is a nice moisturizing treatment for my hands.

Do you like to wash your own fleeces, or are you now intrigued to try it? You can get free samples of the Unicorn Power Scour and Fibre Rinse, which gives you enough for a small scale experiment. Here’s the little bit I’ve spun up so far.

Do you like to wash your own fleeces, or are you now intrigued to try it? You can get free samples of the Unicorn Power Scour and Fibre Rinse, which gives you enough for a small scale experiment. Here’s the little bit I’ve spun up so far.